DESCRIPTION

Part 1. Machine specifications:

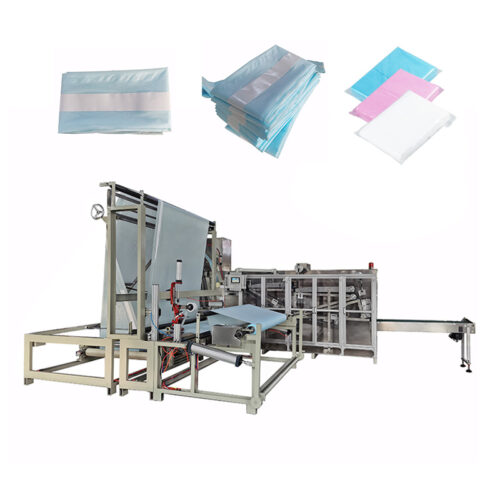

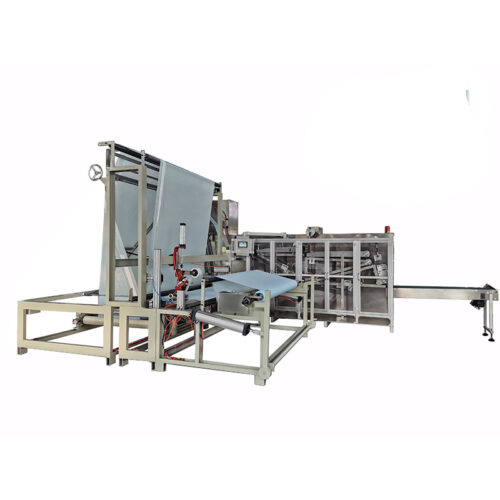

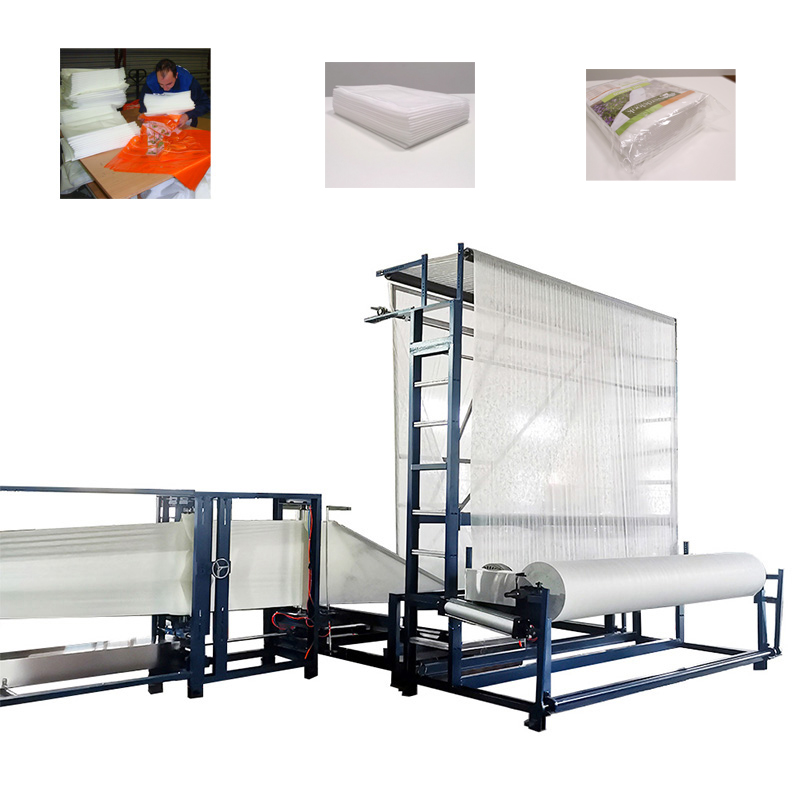

1. 3.2m folding and cutting machine sizes: about 18.00*3.50*2.5m(L*W*H).

а.The maximum width of the material is 3.2m.

b.Folding machine can convert material with the density of 17-80gsm

c.The maximum diameter of raw material roll is 1000mm

d.The inner tube’s diameter of the raw material is 76mm

2. It process: spun bonded nonwoven fabrics,spunlace nonwoven, and nonwoven fabrics laminated.

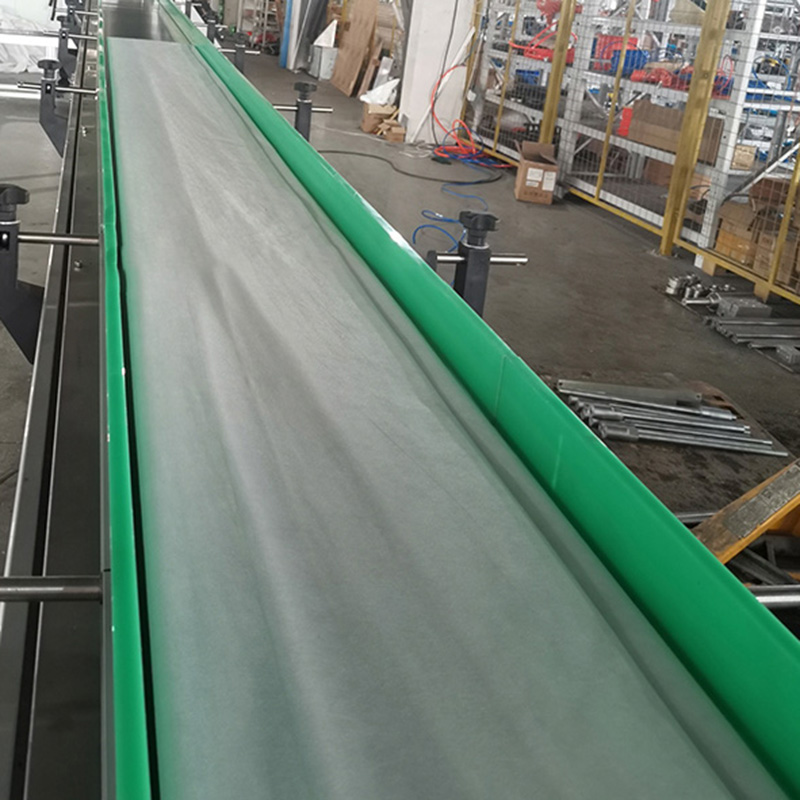

3. Production process: 1. automatic feeding material 2. folding the material into half 3 W folding way through 4 folding devices 4. Cutting the fabrics according to the length needed 5. The folded product output through the belt 6. Folded the folded products again to make the finial folded size 20*28cm.

4. The performance of the machine: A. folding; B. cutting C. Microcomputer control the number counting, you can set the number you want; D. Low speed running and high speed running can be controlled by the computer; E. The folding way in front is W folding. F. The final folding is folded on the horizontal rollers.

5. Producing speed: about 60-90m/min. The tension can be adjusted according to different weight of nonwoven fabrics. PS: we suggest 50m/min for your think fabric like 17gsm, and 60-70m/min for fabric with 30gsm.

6. The folding devices use Chinese good quality stainless steel.

7. Use transducer to adjust the speed of the running. Total power is about 10kw, 380V. The electronic parts are from Xinje, and PLC and touchscreen are from Xinje.

8. The fabrics rewinding machine is made of international standard steel and iron. Use rust-preventing paint to brush the surface of the device. All the bedplates of the machine must use rust-preventing paint. Frame of the device had good jointing and the size is precise. Bracket is fixed strongly.

9. All the standard screws use good 45# and inner hexagon screws.

10. Supplying long-term technique instructing according to different weight of fabric.

Hot selling countries: Non woven mulch machine is well sold in Japan,Uzbekistan, Russia,India etc.

-15.jpg)

-15-100x100.jpg)