DESCRIPTION

Part 1. Machine descriptions:

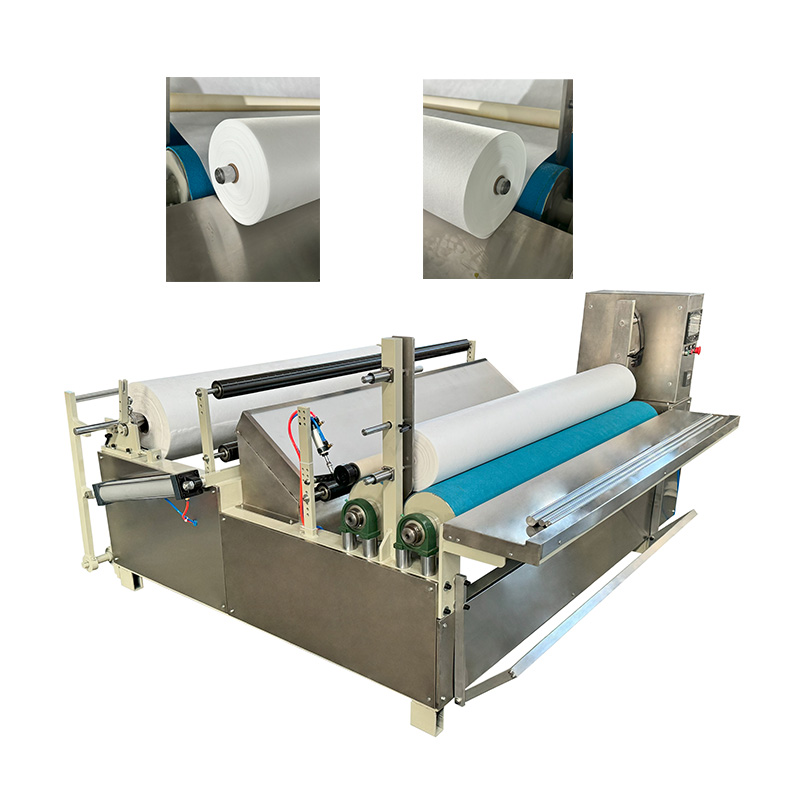

1. Functions: unwinding, inspecting, counting, rewinding and keeping the side surface neat (unwinding part without air shafts as customer’s request, it’s equipped with the common steel shaft together with tapered tubes)

2. The effective breadth 1650mm, the biggest diameter of jumbo roll 800mm.

3. All the rewinding rollers are knurled and plated

4. Automatic meter counting and stop (with inferred) 3.5kw

5. Rewinding with adjustable step-less transmission and the speed can be controlled

6. Equipped with one set of inspection system which is a horizontal testing table with lamp testing device.

7. The maximum speed can reach 100-120m/min (but it depends on the raw materials)

8. It is equipped with one piece of steel roller which can be put into the paper tube.

9. Equipped with one piece of automatic wheel type meter

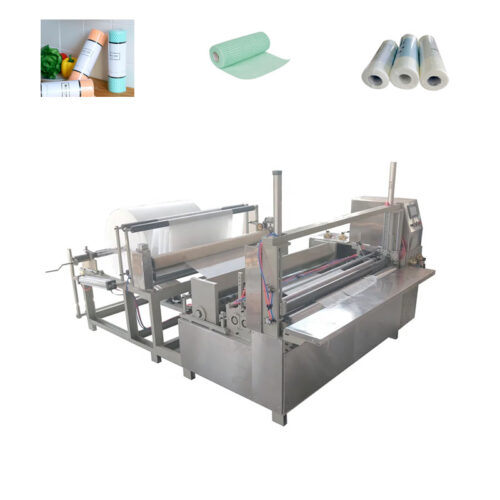

10. Equipped with ONE set of foot switch device (pedal control)

11. Rewinding diameter is from 70- 150mm

12. Equipped with 4 air cylinders, pneumatic material feeding.

13. The whole surface of the machine is anti-rust and the material is stainless steel. High precision welding and secure bracket make the machine run stably and the machine is not corroded easily

14. The high quality of standard screws is 45# steel which reaches the sanitary standard

15. Operation and technical manual in English with detailed instructions with troubleshooting guide

Hot selling countries: Non Woven Fabric Inspection Machine is well sold in Iran, Uzbekistan, Turkey, Russia, Thailand, etc.