DESCRIPTION

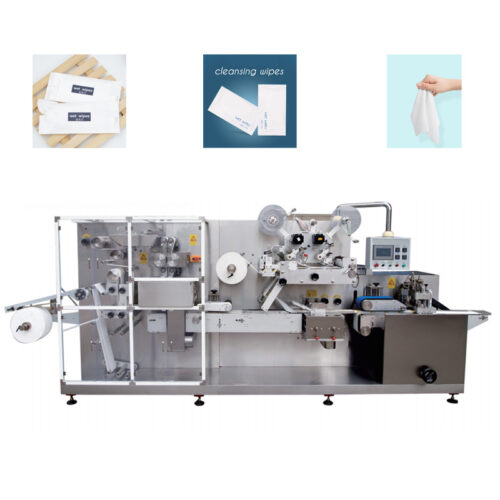

Part1. Machine model: AQ-280:

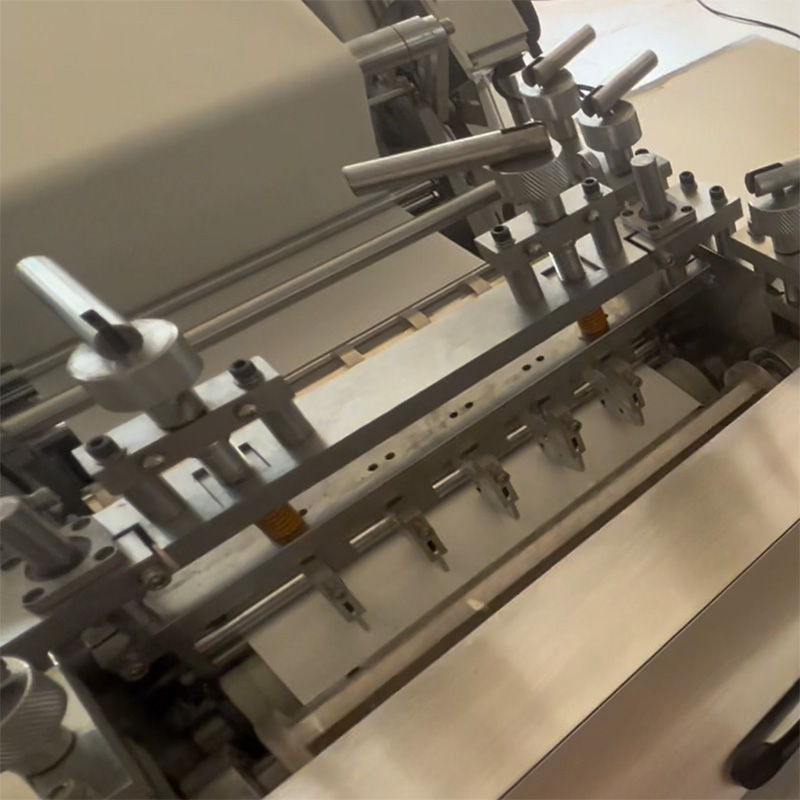

1. Full touch-screen PLC program control;(Panasonic)

2. Touch screen digital setting liquid level, precise injection of liquid level;

3. High-tech numerical control temperature regulator for controlling temperature, precise temperature;

4. Cursor locating;

5. Automatic deviation correction system;

6. Convenient mould replacement;

7. Convenient maintenance and stable operation.

8. Equippedwith the water pump from Italy which can control the chemical amount well

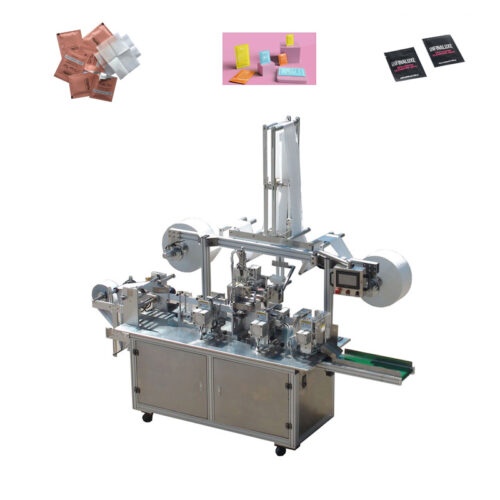

9. It canproduce a single bag, double bag and quadruple bag

10. Equipped with automatic number counting device and delivery system.

Part 2. Machine parameters:

Production rate of 120pcs / min

Rated voltage of 220V

Rated frequency 50Hz

Total power 2.5kw

Air consumption 0.6-0.8Mpa

Part 3. Function and Specification:

Sealing:Four seal

Packaging Material:OPP/PE, PET/PE Φ≤400mm; 100-200mm wide

Material size in the pouch(bag):30-80mm Length; 30-80mm Length

Packaging Dimension:30-100mm Length; 30-65mm Width( It’s regular size)

Material Used Inside:Wet strength paper or Spunlace fabrics; a. 30-60GSM, b. Φ≤600mm, c. 20-50mm wide, d. paper core 76mm

PLC:Language in English; Controls for changing packaging bag length and tissue length with tolerances; Temperature control for heating elements; Temperature control for heating elements(Electrical-heating sealing); Control for production speed; Display of production data including bag length, number of bags produced and pieces/minute

Machine Material:All parts which are in contact with fabrics and liquid formulation are manufactured in 304# stainless steel.

Samples:5Kgs of packaging material of PP and non woven fabrics

Manual:Operation and technical manual in English with detailed instructions with troubleshooting guide

Hot selling countries: Alcohol pad making machine is well sold in Japan, Singapore, Thailand etc.