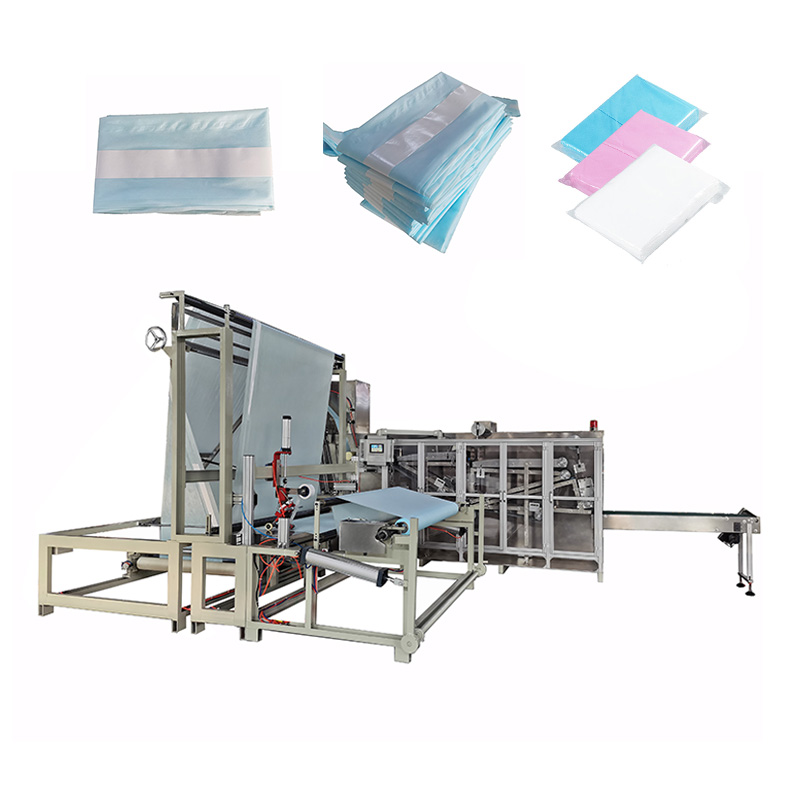

DESCRIPTION

Part 1. The performance structure and characteristics of the equipment:

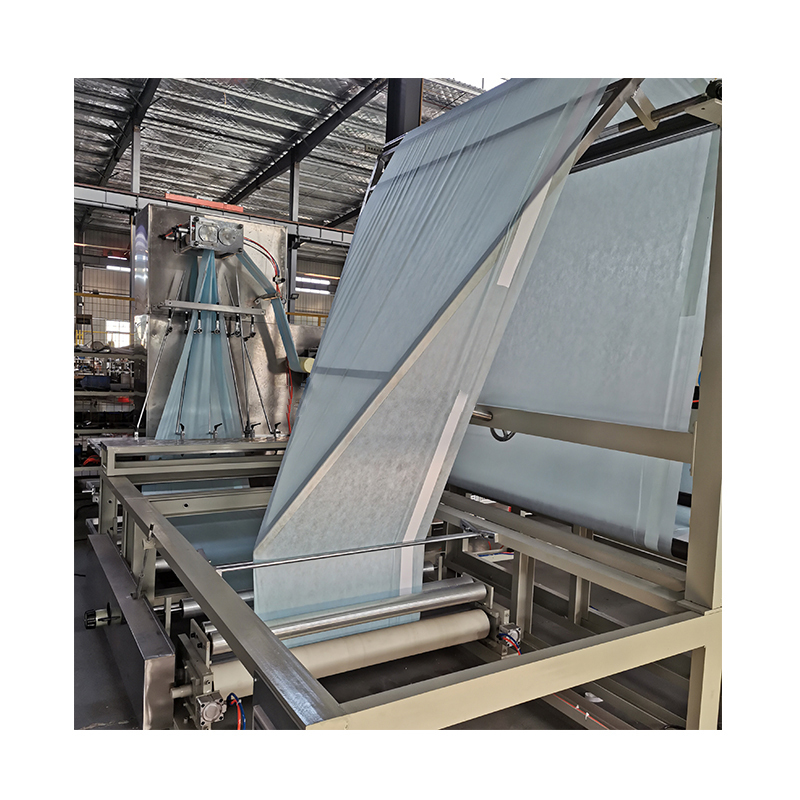

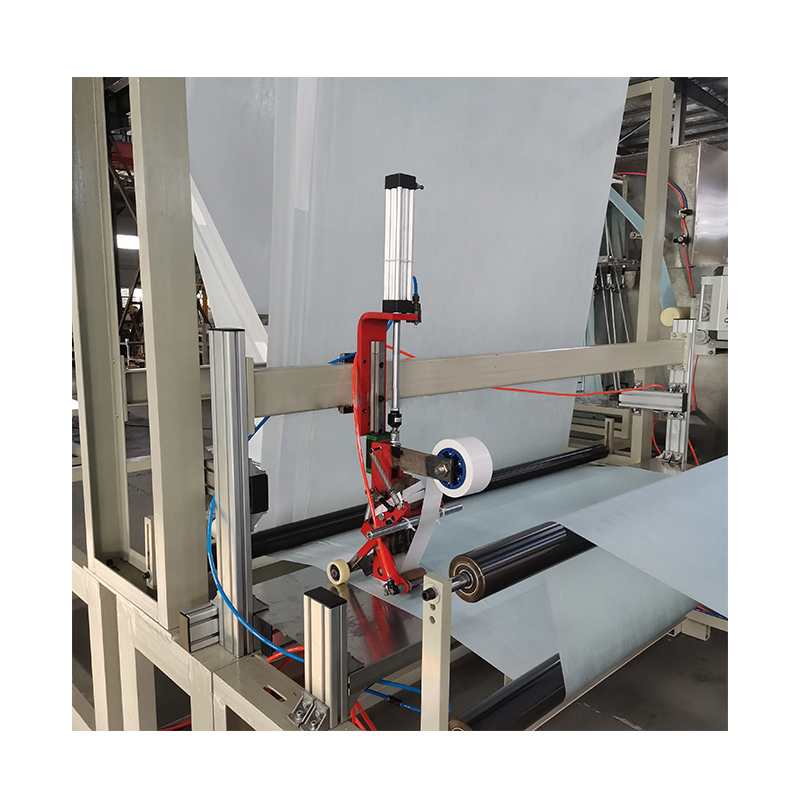

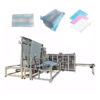

1. The working principle of the equipment: pneumatic material feeding → conveying → double-layer compounding (2 sets of ultrasonic longitudinal welding edges, 12 sets of ultrasonic transverse welding edges) → mold edge punching (banding) → half-folding → feeding → W-shaped folding → fixed-length positioning Cutting→horizontal 3-fold folding→finished product conveying.

2. The medical bed cover making machine is equipped with 14 sets of high-power ultrasonic system molding (screen-following type).

3. The medical bed cover folding machine is equipped with a synchronous conveying device and a magnetic powder tension controller to ensure the dimensional accuracy of the folded product.

4. The medical bed cover making machine is equipped with a set of servo-controlled edge punching molds (quilt cover edge banding type)

5. The nou wowen medical bed cover folding machine is equipped with our factory’s innovative multi-function special-shaped folder, which can convert more product folding methods and is easy to adjust.

6. The medical bed cover machine adopts servo-controlled slider-type lateral fork knife, which can be folded laterally three times at most.

7. The medical bed cover making machine adopts servo control imported cutter cutting.

8. The medical bed cover machine adopts six servos combined with PLC programming controller and microcomputer display screen to jointly control the production. The production parameters are clear at a glance and easy to operate.

9. The medical bed cover folding machine shell is made of stainless steel.

10. The medical bed cover making machine has advanced design concept, compact structure, fast speed, good stability, high production efficiency, and meets the requirements of various national health standards.

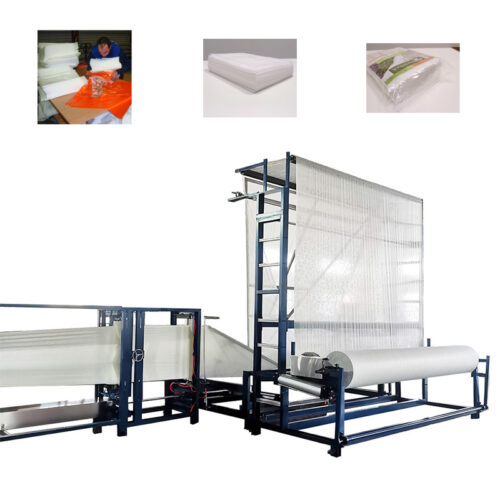

Part 2. Technical parameter Control system:

1. Maximum cross-cutting size 2400mm (adjustable)

2. Folding times 3 times

3. Raw material unwinding maximum roll diameter 1000mm

4. Raw material width range 2000 (unit: mm)

5. Folding Process Continuous Folding Signal

6. Expanded size width 1500-2400*length 1500-2400 (unit: mm)

7. Folded size (width) 150-180 (unit: mm)

8. Folded size (length) 320-360 (unit: mm)

9. Hob Model Customized

10. Raw paper tube Standard 3 inches

11. Rated frequency 50HZ

12. Servo Control System Jiangsu Huichuan

13. Longitudinal welding ultrasonic 2 sets

14. Servo motor quantity 6 sets

15. 12 sets of transverse welding ultrasonic wave equipped with device

16. 1 set of edge punching mold (banding)

17. Longitudinal Folding Mode Adjustable

18. Various Types Loading Pneumatic

19. Horizontal folding method Half fold

20. Whole machine: length*width*height 6500mm*5500mm*2700mm

21. Counting automatic

22. Host power 8KW

23. Main engine speed 1400r/min Air compressor None

24. Application tools A set of special toolboxes.

25. Host speed control 6 sets of servo joint control

26. Input power 380V three-phase four-wire

27. Hob cross-cutting length Servo control

28. Actuating device (contactor, etc.) Chint products

29. Components (Photoelectric Switching, etc.) Omron Products

30. Pneumatic components AirTAC products

31. Counter Chint Products

32. Inverter Delta

33. Number of Inverters 1

Hot selling countries: Medical bed cover making machine is well sold in India, Malaysia, Thailand etc.