DESCRIPTION

P

Part1. Product Details:

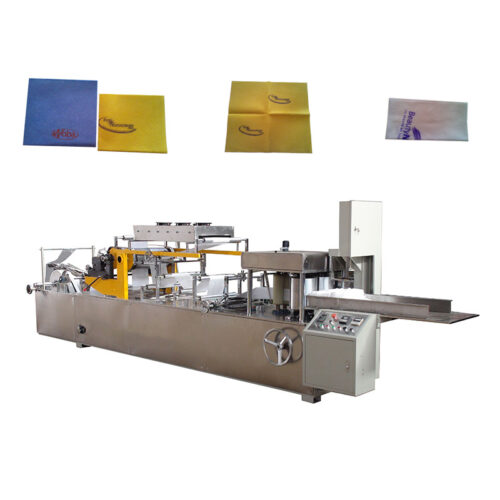

1. 280mm folding machine sizes: about 3.85*1.05*1.75m(L*W*H).

2. Each M-F machine is named as per their product’s fixed length and for the machine, the sizes you can make on the machine as follows: M-F(280), the sizes you can make: 280*230mm,280*250mm,280*280mm, 280*330mm.etc

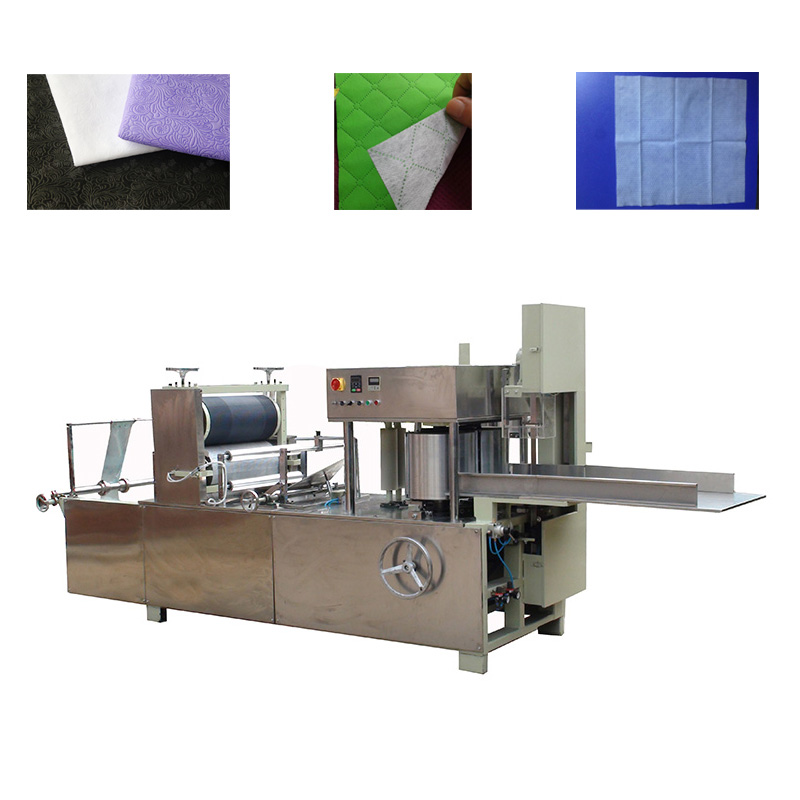

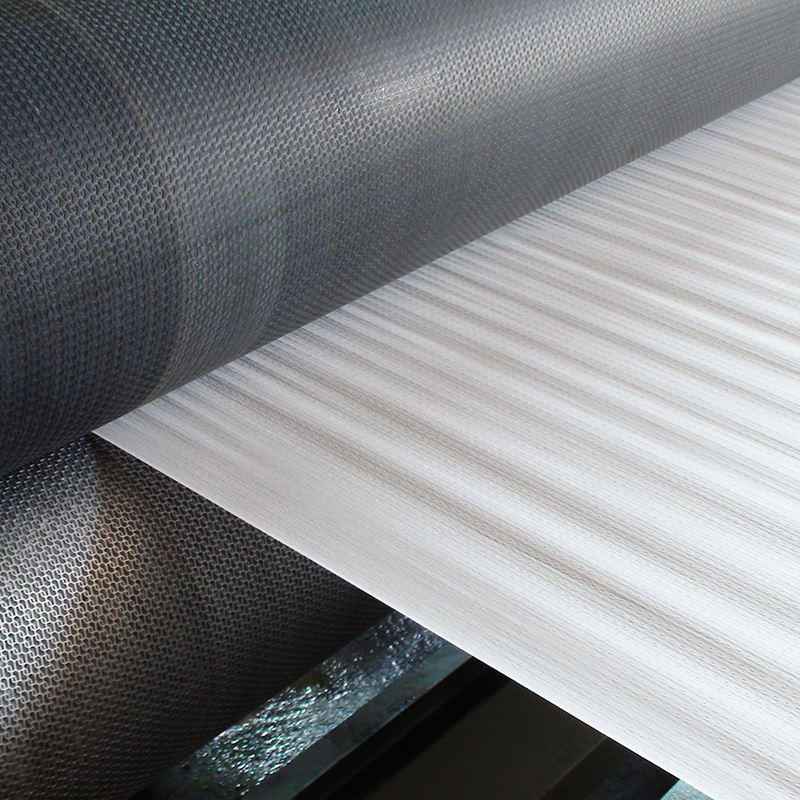

3. It can process: a. spunlace nonwoven; b. airlaid paper, c.wood pulp material, d.composite nonwoven materials,etc.

4.The performance of the folding and cutting machine: A. folding B.embossing C. cutting, use band-saw to cut the folded cloth which has neat cutting edges; D. Pneumatic counting the slices. You can set the number you want; E. Low speed running and high speed running can be adjusted by stepless speed adjusting device; F. The folding way be changed as C,Z,1/4 folding, etc.

5.The working table of the folding and cutting machine uses thicker iron board. The wheel of band saw has been technically processed. Enwrap the special cloth on the surface of this wheel to lower the noise.

6.The tail shelf of the machine installs the broad-strap synchronous transferring device to control the tension of the cloth.

7. Producing speed: about 300-450pcs/min. This machine can adjust the tension according to different types of nonwoven fabrics.

8.The folding rollers use Chinese good quality 45# steel. The plywood use good quality stainless steel. The middle of the machine uses screw rod to adjust the windage of the nonwoven fabric which can finish many kinds of foldings. The tail of the machine uses double brackets to make the machine more stable.

9. Axletrees use Chinese good quality 45# steel. The machine has automatic shaping knife and automatic counting functions. ( a. lower the noise of counting; b. enlarge the radian of the slip pieces under the folding rollers to lower the noise; c. the device use double transferring devices and gears positioning to make the folding more stable; d. easily change the band-saw knife; e. controlling board uses stainless steel; f. use imported band-saw knife).

10. Axletrees use Chinese good quality 45# steel. The distance from the band-saw knife to the tail of the machine is about 0.8m.

11. Use transducer to adjust the speed of the running. Total power is 3.5kw,380V. The electronic device has reasonable wire fixing and easily operation.

12.The whole machine is made of international standard steel and iron. Use rust-preventing paint to brush the surface of the device. All the bedplates of the machine must use rust-preventing paint. Frame of the device had good jointing and the size is precise. Bracket is fixed strongly. Strap wheel, gears and all the driving parts are Centro symmetric. The main gears are easily adjusted to promise the stable running of the device. We offer 2 years quality guarantee for the main parts of the machine (except the human reasons).

13. All the standard screws use good 45# and inner hexagon screws. We use all 304# stainless steel to make the parts which can affect the products’ sanitary and other quality (the thickness of the stainless steel is 1.0mm-4.0mm). All the electroplating parts are electroplated two times to promise the fine surface of the machine. We promise the machine will not be rusted in 2 years.

14. The device installs front and reverse cloth-guiding conversion device (only our factory makes this device on the machine in China.)

15. Supplying long-term technique instructing according to different kinds of clothes.

16. Operation and technical manual in English with detailed instructions with troubleshooting guide.

Hot selling countries: Non woven embossing and folding machine is well sold in India, Russia, Vietnam, Thailand, etc.

-11.jpg)

-11-100x100.jpg)