DESCRIPTION

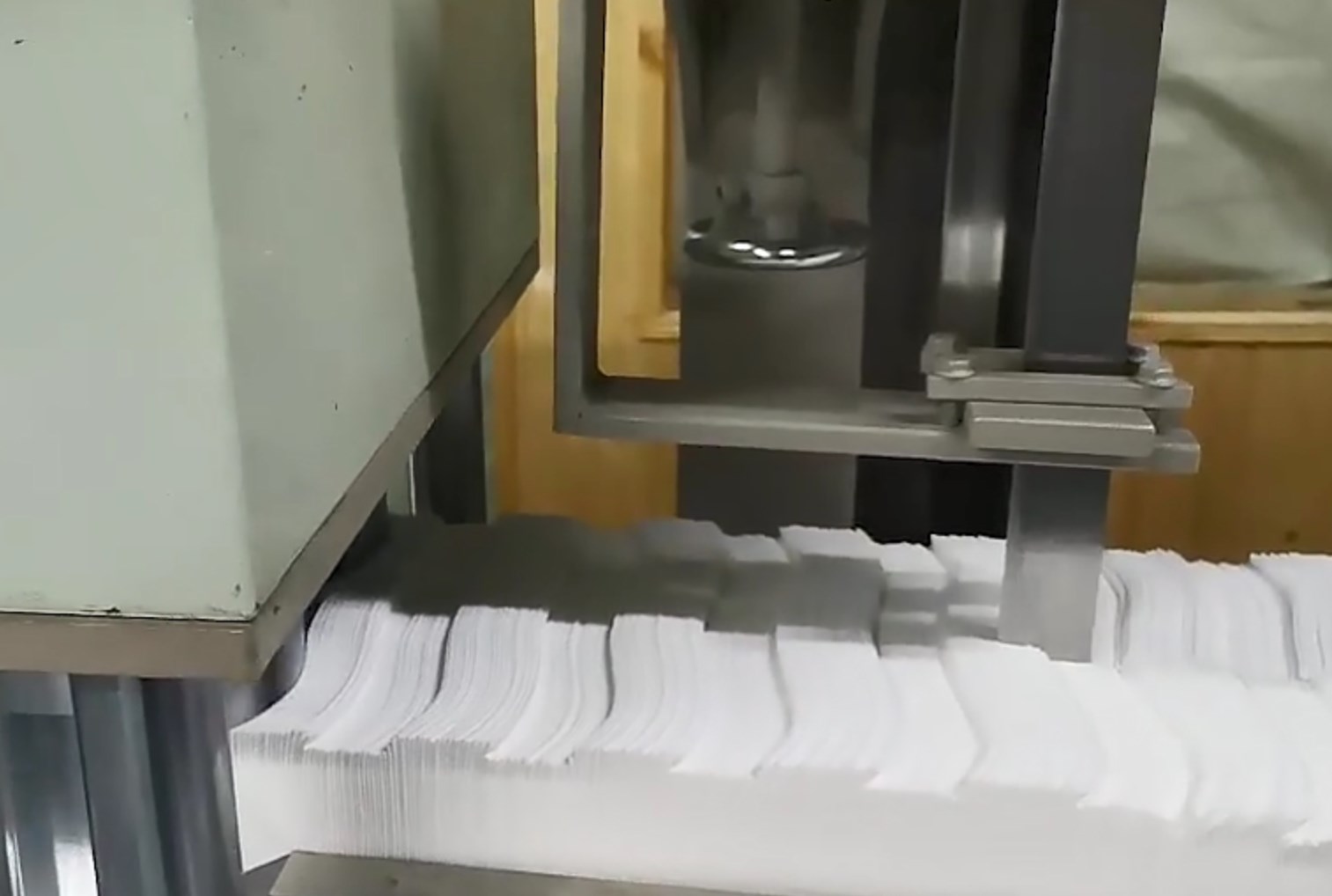

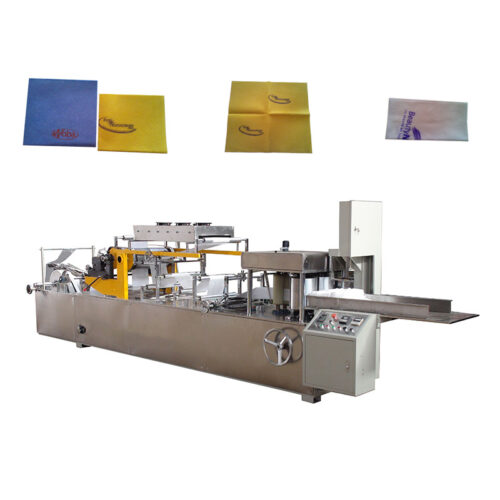

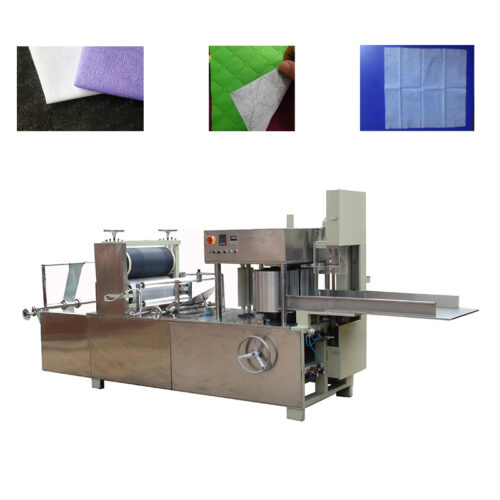

This page focuses on the AQ-F (150-1000) folding machine. It is a versatile non-woven machine that is designed to handle various non-woven materials through am automatic one-stop process from embossing to folding, counting and cutting.The Non-Woven Fabric Folding Machine comes with an automatic embossing function, allowing it to produce clear and beautiful embossing patterns as needed. Products manufactured by the fabric folder do not need to be folded manually. In addition, our non-woven fabric embossing, folding and cutting machine has a speed of 300-500 sheets/minutes at a folding size of 150-1000 mm. It can also fold into various shapes, including an N, a W, folding in half and other special shapes.We are a non woven folding machine manufacturer, it is a folding machine for non woven fabric, it is automatic non woven fabric folding machine, and it is a non woven fabric folding machine. And it is a non woven folding and cutting machine.

Part1. Features of Non-Woven Fabric Folding Machine:

1. This folding machine is designed with a constant heating system, which contains temperature control devices and relevant electrical components, making the temperature adjustable.

2. A synchronous broad belt conveying device and a tension control device ensure the size accuracy of the finished product.

3. The machine uses an air operated counting device, and is equipped with both forward ad reverse web guiding devices.

4. The non-woven fabric folding machine comes with a specially designed shape folder that ensures a variety of folding patterns.

5. The drive part on the textile machine utilizes gear movements to eliminate the gear clearance. It can also be outfitted with a static eliminating device.

6. Our folding machine works with variable frequency speed control systems, allowing easy operation.

Part2. Benefits of Non-woven Fabric Folding Machines:

1. Increased Efficiency: Non-woven fabric folding machines are designed to fold and cut non-woven fabrics with high precision and at a much faster rate than manual labor. This boost in efficiency not only reduces production time but also saves on labor costs.

2. Precision and Consistency: These machines are equipped with advanced technology that ensures precise folding and cutting, resulting in uniform product dimensions. This consistency is crucial, especially in industries where non-woven fabrics are used for medical supplies, ensuring that products meet stringent quality standards.

3. Waste Reduction: By optimizing the cutting and folding processes, non-woven fabric folding machines minimize material wastage. This not only contributes to cost savings but also aligns with sustainability goals as less material ends up in landfills.

Hot selling countries: Non-Woven Fabric Folding Machine is well sold in India, Vietnam, Thailand, Russia, Malaysia etc.