DESCRIPTION

Part 1.Application:

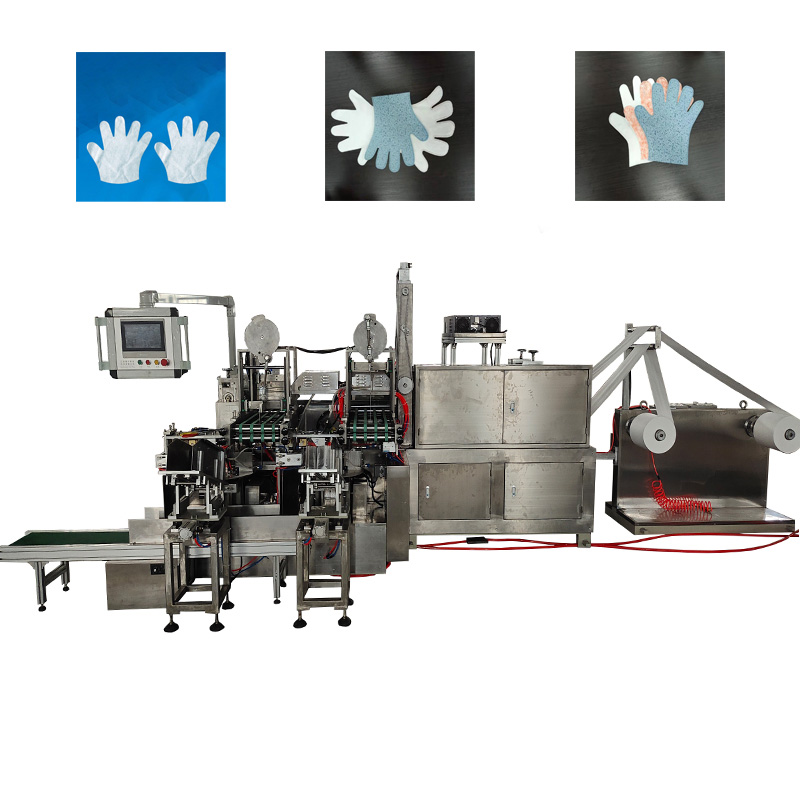

The ultrasonic gloves making machine is used to produce warm, velvet inner sleeves that go inside of gloves, including antistatic or polyester gloves. These sleeves are available in a variety of shapes and specifications. The equipment can also produce a pair of gloves simultaneously, thus ensuring a high production efficiency.

Part 2.Production line working principle:

Double roll non -woven raw materials → two groups of ultrasonic embossing → feeding composite → ultrasonic gloves → glove mold cutting → glove forming → automatic first folding → automatic second fold → automatic packing → automatic filling liquid→ automatic seal → finished product output.

Part 3.Features:

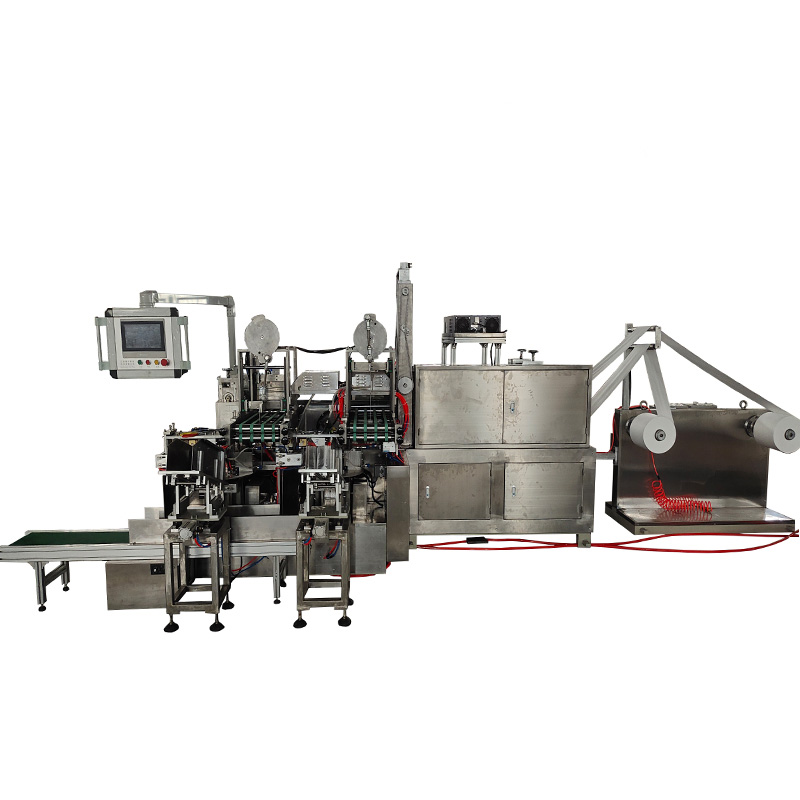

1. The whole machine utilizes an aluminum alloy rack, which features a rational, strong and durable structure.

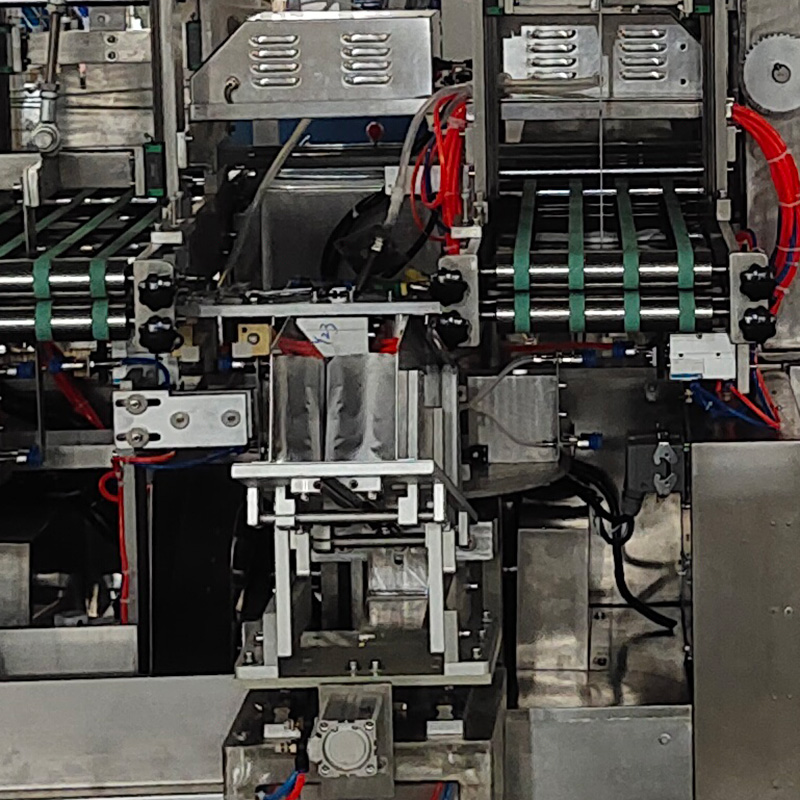

2. Utilizing ultrasound technology there is no needle or thread sewing.

3. Electronic counting, with automatic shutdown at the set output.

4. Easy operation, high production efficiency.

5. Machine with semi-auto ultrasonic fabric connection device

6. Applicable materials :Chemical fiber cloth, non-woven fabric, polyester fabric, Nannie cloth, warm velvet, nylon, thermoplastic film and chemical plastic slice.

| Item Name | Nonwoven gloves making machine |

| Applicable Industries | Hotels, Manufacturing Plant, Home Use, Retail, Other |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | New Product |

| Warranty of core components | 1 Year |

| Core Components | PLC, Motor |

| Weight | 2500kg |

| Automatic Grade | Automatic |

| Place of Origin | China |

| Production Speed | 30-40 bags/min |

| Key Selling Points | Automatic |

| Machine Type | Embossing cutting folding packing production line |

| Dimension | 6000*2000*1800mm(L*W*H) |

| Electrical Source | 380V/50Hz |

Hot selling countries: Non woven gloves making machine is well sold in Japan, Russia, Vietnam, America etc.

-12.jpg)

-12-100x100.jpg)