DESCRIPTION

Part 1. Product description:

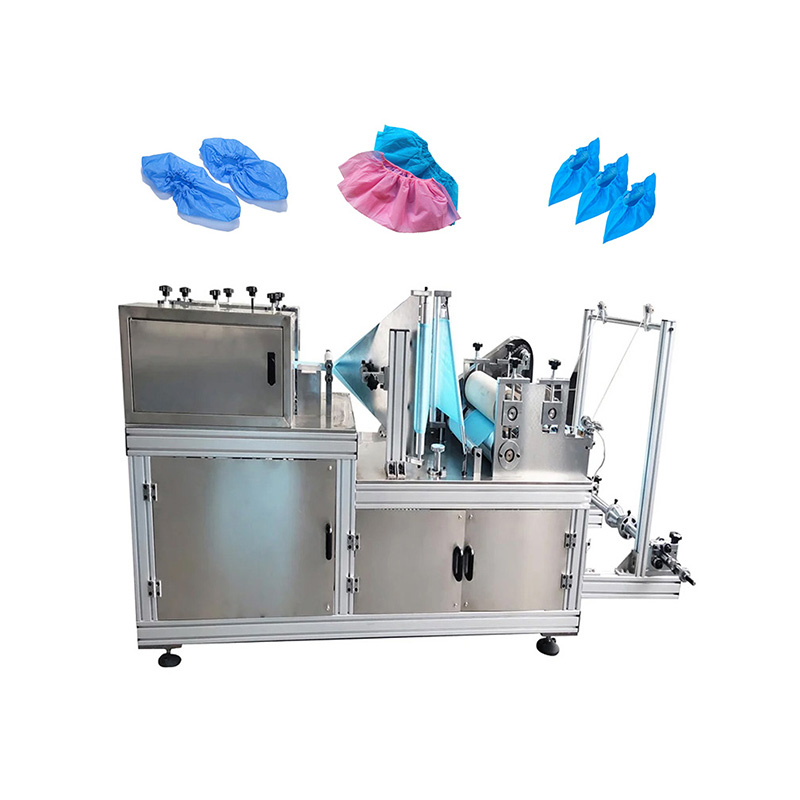

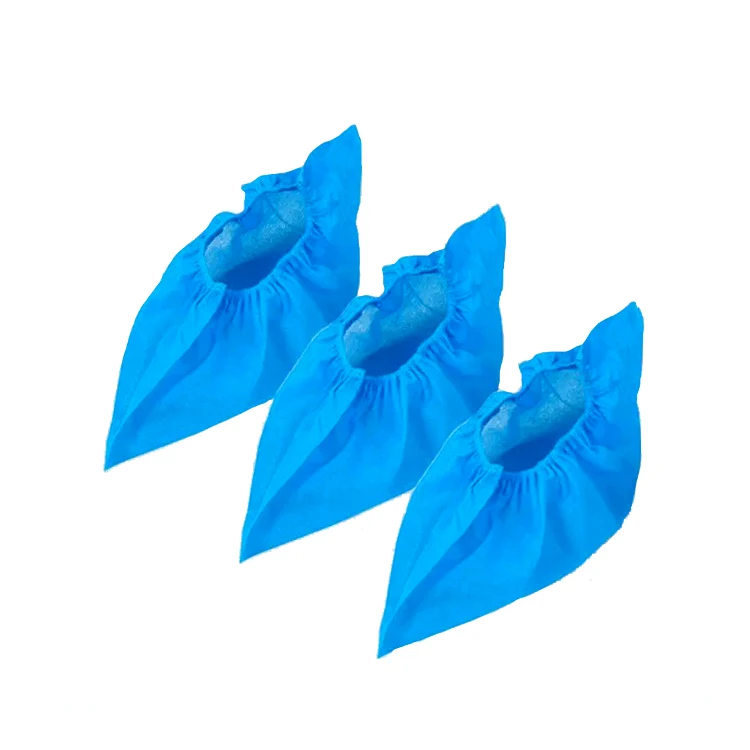

The machine is makin shoe cover with the material PP nonwoven, which is welded by the ultrasoic technology. The finished shoe covers are applicable to hospitals and other environments that need to remain hygienic. The machine is fully automatical, including automatic feeding, all the way to the finished product, with no need for manual operation.

Part 2. Features:

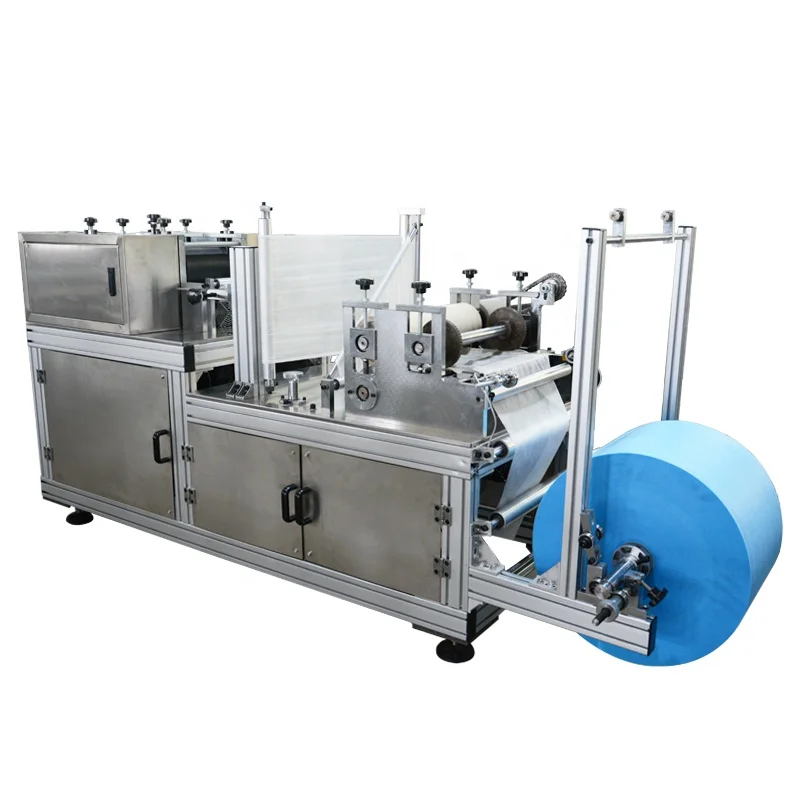

1. Aluminum alloy rack, strong, durable and solid structure.

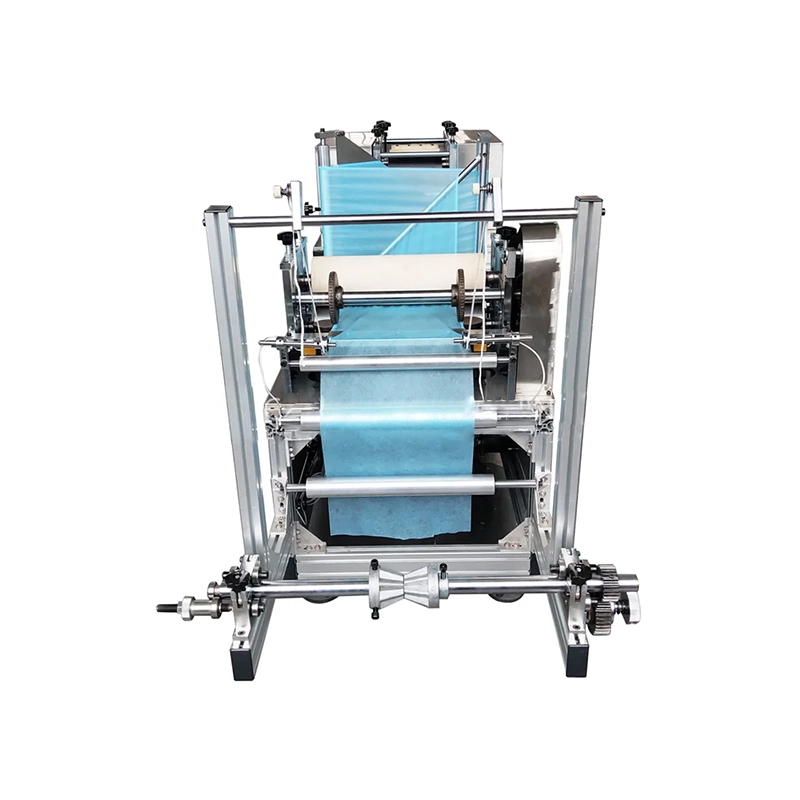

2. The imported ultrasonic system features a strong and stable power that is applicable to long-term continuous operation.

3. Easy to operate and convenient to maintain.

4. It runs smoothly, the fastest speed is 120 pieces per minute, and the product qualified rate is 99% and above.

5. Electronic counting, automatic shutdown at the set output. If the shoe strap is broken, the equipment will automatically stop.

6. Automatic feeding – nonwoven fabric binding and welding – nonwoven fabric folding – forming welding – cutting off – finished products output

7. Applicable to 25~40gsm thick nonwoven fabrics, 330~430mm wide raw materials.

Part 3. Machine parameters:

Model: AQ-SC400

Power supply: 220VAC, 50/60Hz, 3KW, 1Phase

Ultrasonic Frequency: 20KHZ

Shoe cover size: 400*160mm

Production speed: 100-120pcs/min

Dimension(L*W*H): 2500*800*1200mm

Net weight: about 620Kg

Gross weight: about 710Kg

Model: AQ-SC400

Power supply: 220VAC, 50/60Hz, 3KW, 1Phase

Ultrasonic Frequency: 20KHZ

Shoe cover size: 400*160mm

Production speed: 100-120pcs/min

Dimension(L*W*H): 2500*800*1200mm

Net weight: about 620Kg

Gross weight: about 710Kg

Hot selling countries: Non woven shoe cover making machine is well sold in Poland, Japan, Russia, Portugal,Vietnam etc.