DESCRIPTION

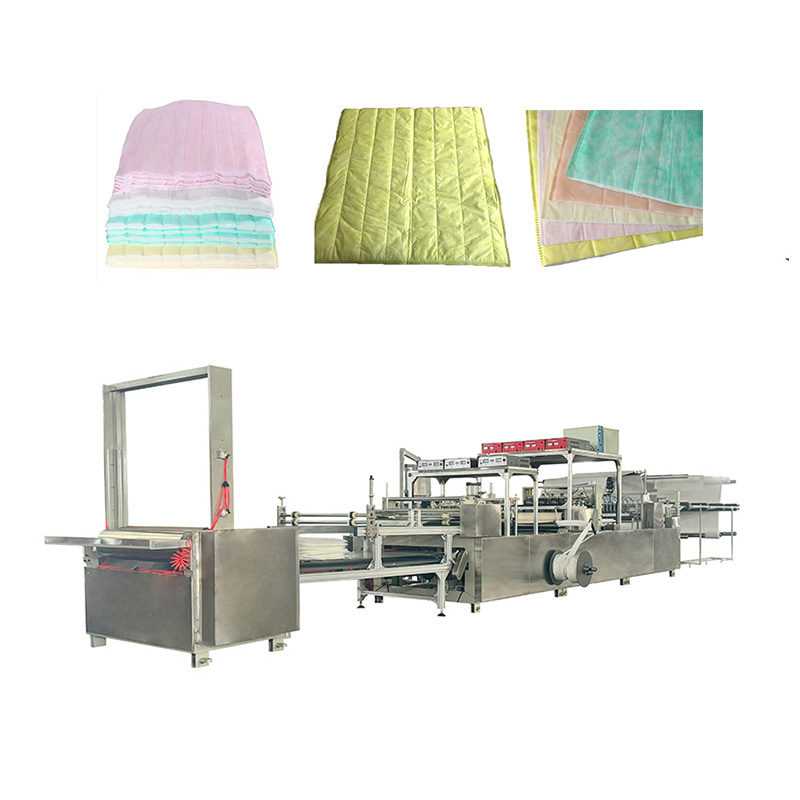

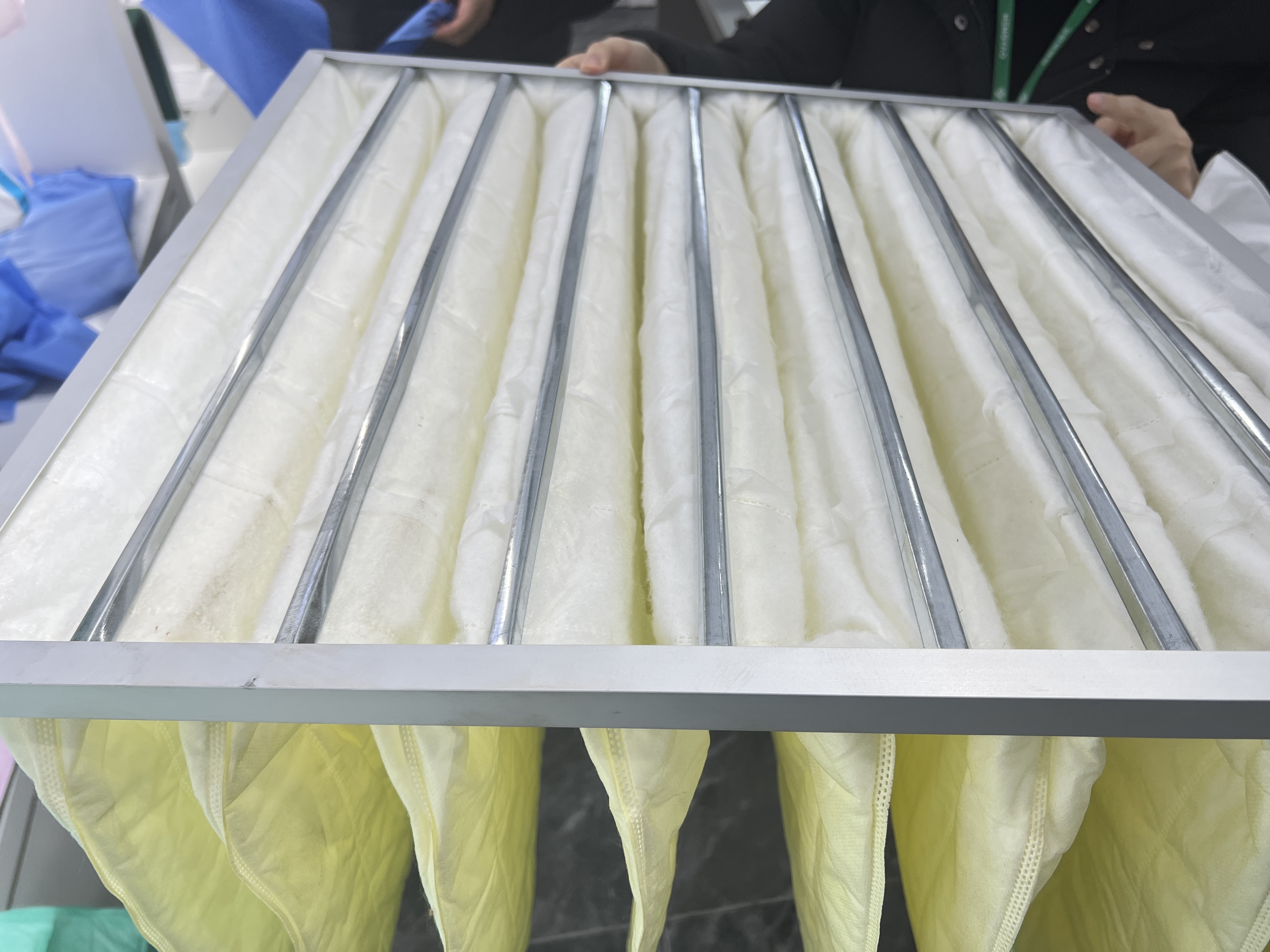

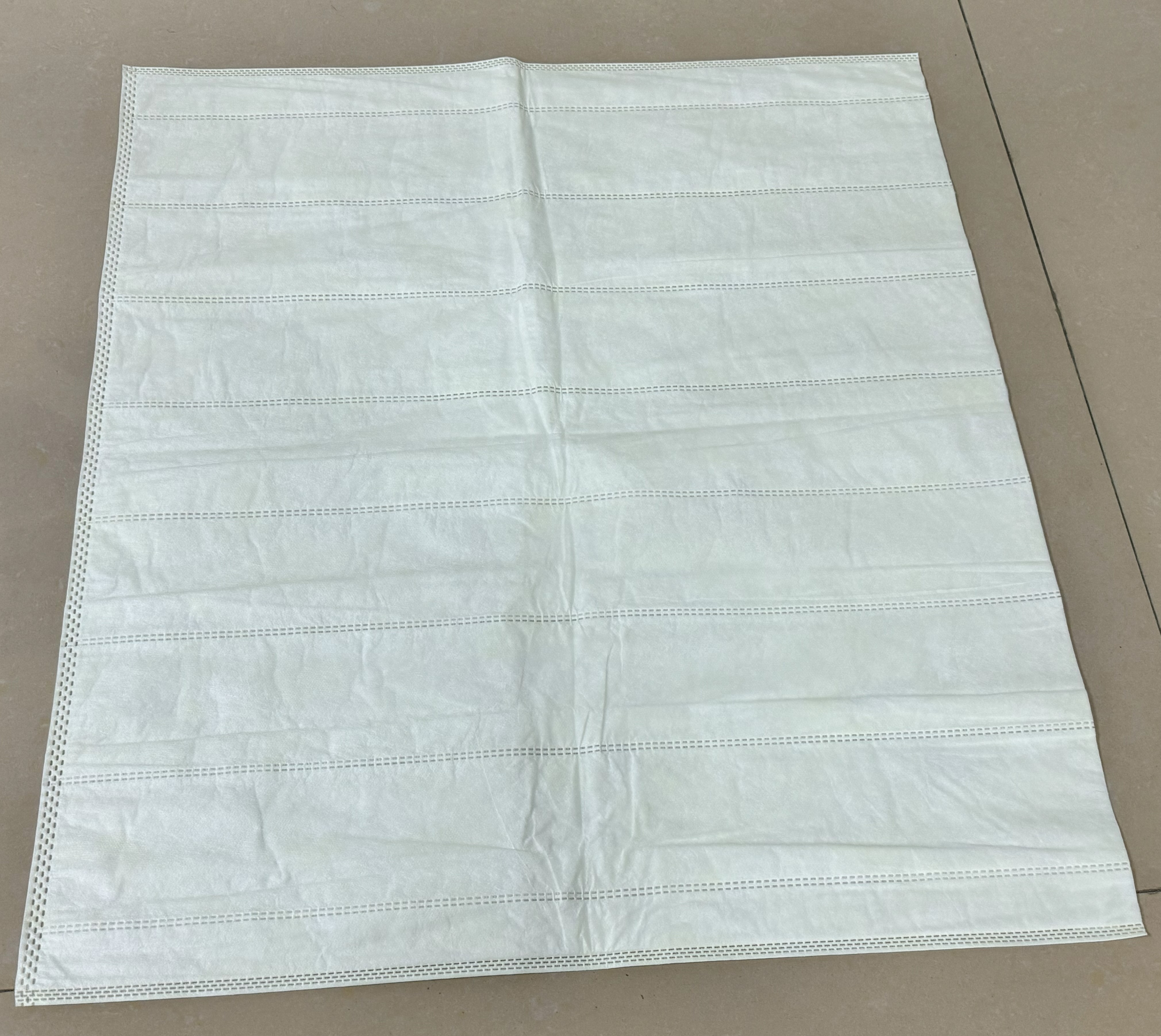

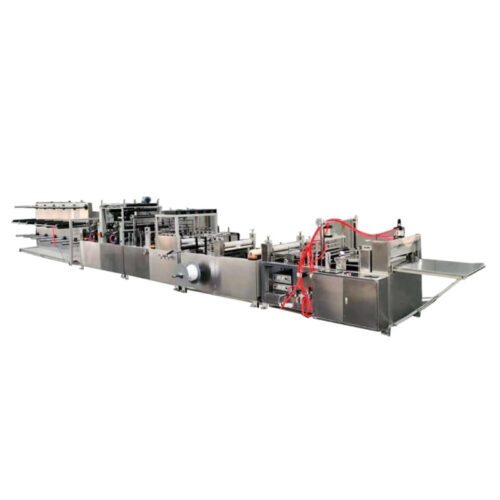

The Pocket Filter Bag Making Machine is an advanced manufacturing solution designed for the efficient production of high-quality pocket filter bags used in various filtration systems. This machine incorporates cutting-edge technology, ensuring precision in bag dimensions, seamless welding, and reliable performance. With user-friendly controls and automated processes, it streamlines production, making it an ideal choice for industries requiring top-notch pocket filter bag manufacturing capabilities.

Part1. Machine description:

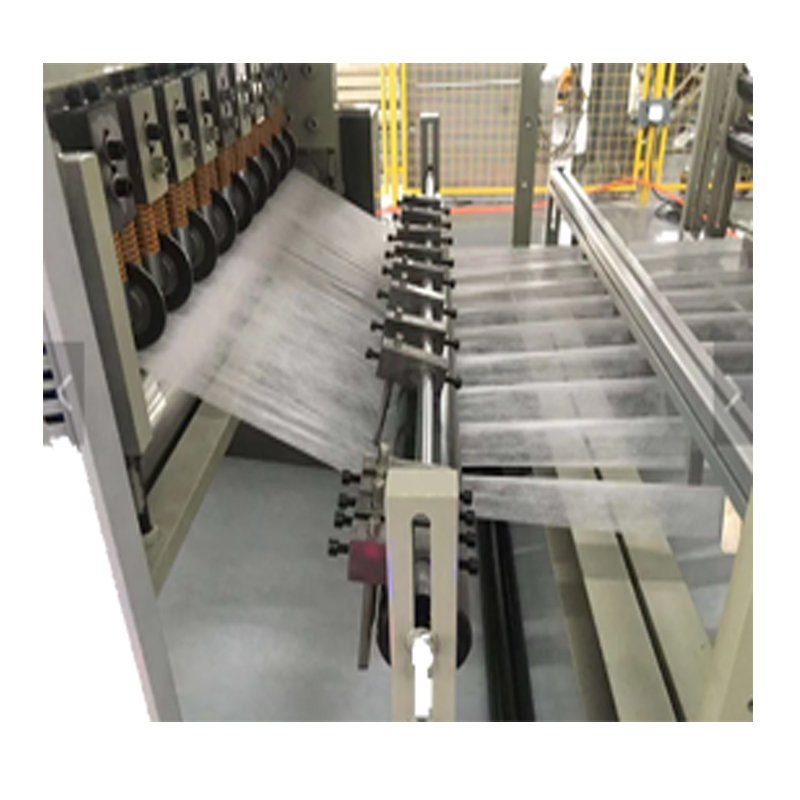

1.Equipped with 9 pieces of unilateral support raw material loading devices, with a maximum fabric width of 760mm; with maximum roll diameter 1000mm, with 3” paper tube.

2.Equipped with 9 pieces of air swelling shafts to hold the material, and equipped with hand shaking adjustment position device.

3.Equipped with 9 sensors to control the machine automatic stop if without material on any one of air shafts.

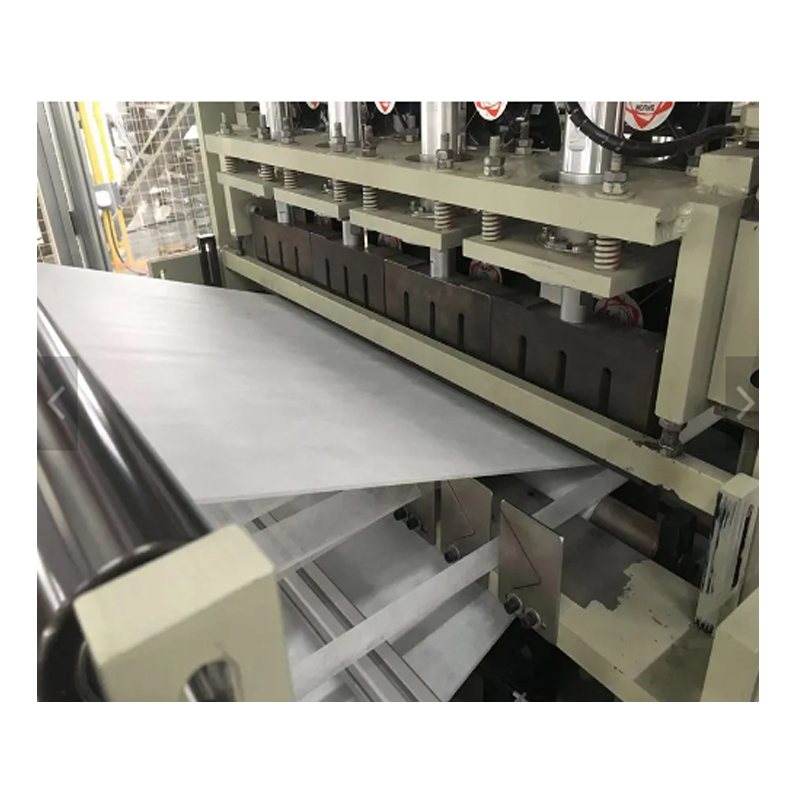

4.Equipped with 8 sets of 20K ultrasonic units and 10 sets of 15K ultrasonic units on the machine, and which has cooling system including fan and air conditioner.

5.Customized space distance is 40mm.

6.Customized open mouth distance is from 50-200mm.

7.Product cutting length is ≥200mm.

8.No paper core rewinding with one piece of smooth steel roll.

9.Two methods for making final products, one is piece stacking and the other one is rewinding.

10.The piece stacking part and rewinding part are movable according to the production needs.

11.Use 3 languages in the touchscreen which has Chinese, Turkish and English.

12.It’s equipped with 6 servo motors and anti-interference system, PLC, touch film screen, and joint control of imported photoelectric tracking system(Servo motors all adopt the Taiwan Delt ).

13.It’s equipped with waste collecting device which are on the both sides of the machine. It’s with automatic left and right winding device which the waste can be re-winded.

14.Horn material is steel.

15.It has the pressing roller which automatically or manually press on the re-winded roll to ensure the tension of it.

16.Production speed:15-20m/minute.(Depending on the weight of the fabric, size of the bag, etc.)

17.All conveying guide rollers of the equipment are made in China.(the best hard oxidation reinforced aluminum roller in Shanghai).

18.All molds of equipment are made of good quality special materials, and the indentation pattern is carved by special process computer(patterns can be made as required).

19.Machine size about : total length 13.8 meters and width 1.2 meters. And machine weighs about 4t.

20.Basic operation procedure of equipment, raw material winding,slitting, trimming, weilding, cutting, product output, system design photoelectric tracking or length mode operation!

21.Machine total power: about 42kw,rated voltage of 380V, 3-phase,50Hz.

22.Whole machine frame is made of national standard forming steel(No.12 U-steel),the surface is anti-rust spray paint treatment, accurate machine frame welding size, proper bracket reinforcement, pulley, umbrella gear and all transmission parts, accurate center, and the main gear slice treatment, easy to adjust the gap to ensure the smooth operation of the machine.

23.The standard parts screws are all made of domestic high-quality 45#steel and internal hexagonal screws, and the parts that are easy to affect the finished product are all made of no rust. All electroplating parts of the machine are good, to ensure the cleanliness of all parts of the machine, rust resistance.

Hot selling countries: Pocket Filter Bag Making Machine is well sold in India, Poland, Japan, Russia, Thailand etc.